Nextreme Thermal Solutions推出更小更強大的薄膜熱電冷卻器(E)

Nextreme Thermal Solutions, the leader in microscale thermal and power management products for the electronics industry, today announced the availability of the OptoCooler HV series, a new class of RoHS-compliant high voltage and high heat pumping thermoelectric coolers that are optimized for standard circuitry and power requirements. The first module in the series, the OptoCooler HV14, is the latest product in Nextreme's OptoCooler(TM) family of thermoelectric coolers designed specifically for the optoelectronics and telecommunications industry.

The OptoCooler HV14 operates at a maximum voltage of 2.9V and can pump 1.7 watts of heat at 85癈 in a footprint of only 2.8 mm2. The module can create a temperature differential (DeltaT) of up to 51癈 between its hot and cold sides, making it ideally suited for the cooling and temperature control of optoelectronic devices such as laser diodes and high brightness LEDs.

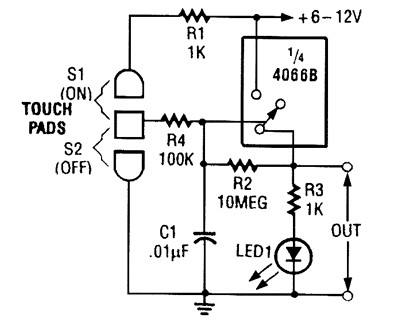

At the core of the OptoCooler module is Nextreme's breakthrough Thermal Copper Pillar Bump, an electronic device made from thin-film thermoelectric material embedded in flip chip interconnects (in particular, copper pillar solder bumps) used in electronic and optoelectronic packaging. Thermal bumps act as solid-state heat pumps and add thermal management functionality locally on the surface of a chip or other electrical component. Based on market demand and recent technology advances, Nextreme has reduced the size of the thermal bump by 75%, thereby increasing voltages by 300% and reducing current draw by the same proportion. The net result eliminates the need for special voltage conditioning and reduces the overall electrical current required to operate the device.

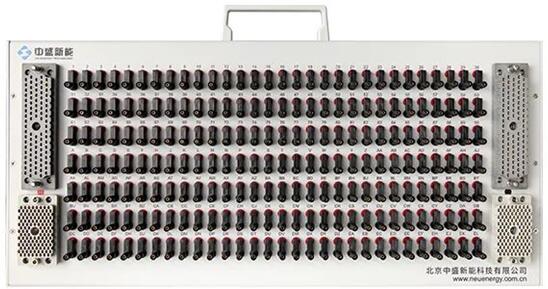

The new platform uses an array-based assembly (ABA) process that represents a vast improvement in throughput capability and manufacturing tolerances. The ABA process decreases the size of Nextreme's thermal bumps to approximately 125 microns, which makes them flip-chip bumping compatible with standard solder bumping processes commonly used in electronics packaging. Consequently, as product volumes scale, manufacturers of LEDs and other semiconductor chips can integrate cooling and temperature control functionality directly in the package during assembly, resulting in a high-volume, low cost thermal management solution.

"The new HV Series removes unique voltage and current requirements as barriers to the integration of thin-film thermoelectrics into electronics," said Dave Koester, Vice President of Engineering for Nextreme. "The standard voltages and current operating ranges of the new OptoCooler HV14 fit well within the typical power design criteria for optoelectronic components and systems."

The OptoCooler HV14 is RoHS compliant and is available for order now. Pricing is available upon request.

相關閱讀:

- ...2017/01/06 17:05·Imagination與Socionext合作開發先進的視頻與顯示技術

- ...2017/01/06 14:16·Imagination與Socionext合作開發先進的視頻與顯示技術

- ...2016/11/24 22:03·CEVA 和NextG-Com合作提供面向低成本IoT應用市場的 集成式LTE Cat-M1 和 Cat-NB1 解決方案

- ...2016/04/27 10:23·全球領先的移動應用分發和變現平臺Appnext戰略進軍中國市場, 成功實現快速擴展與增長

- ...2016/04/26 10:01·Appnext與海信集團攜手提供完全定制的 移動應用體驗

- ...2015/12/10 11:20·LG Nexus™ 5X 智能手機選用 Qorvo RF Fusion™ 移動 Wi-Fi iFEM模塊

- ...· Efinix® 全力驅動AI邊緣計算,成功推出Trion™ T20 FPGA樣品, 同時將產品擴展到二十萬邏輯單元的T200 FPGA

- ...· 英飛凌亮相進博會,引領智慧新生活

- ...· 三電產品開發及測試研討會北汽新能源專場成功舉行

- ...· Manz亞智科技跨入半導體領域 為面板級扇出型封裝提供化學濕制程、涂布及激光應用等生產設備解決方案

- ...· 中電瑞華BITRODE動力電池測試系統順利交付北汽新能源

- ...· 中電瑞華FTF系列電池測試系統中標北京新能源汽車股份有限公司

- ...· 中電瑞華大功率高壓能源反饋式負載系統成功交付中電熊貓

- ...· 中電瑞華國際在電動汽車及關鍵部件測評研討會上演繹先進測評技術