Nextreme Thermal Solutions推出采用金/錫互連的薄膜熱電冷卻器和功率發生器(E)

Nextreme Thermal Solutions, the leader in microscale thermal and power management products for the electronics industry, today announced that future thermoelectric products will be manufactured using RoHS-compliant assembly methods. The company has developed non-lead-based solder processes for use in the manufacturing of its thin-film thermoelectric product line, meeting a major milestone in contributing to a healthier environment.

The Restriction of Hazardous Substances (RoHS) directive restricts the use of hazardous materials, including lead-based solder, in the manufacture of various types of electronic and electrical equipment. The directive was adopted in 2003 by the European Union (EU) in an initiative to address the growing global issue of substances found in consumer electronics waste that pose health risks. Although the EU has led the RoHS initiative, companies like Nextreme who are in the global electronics supply chain have followed suit in making their products RoHS compliant.

"RoHS compliance is becoming critical for companies like ours that operate in a global environment," said Dave Koester, vice president of engineering for Nextreme. "In addition to the health and environmental benefits of going lead-free, it's far more cost-effective to offer a product family that conforms to the world standard."

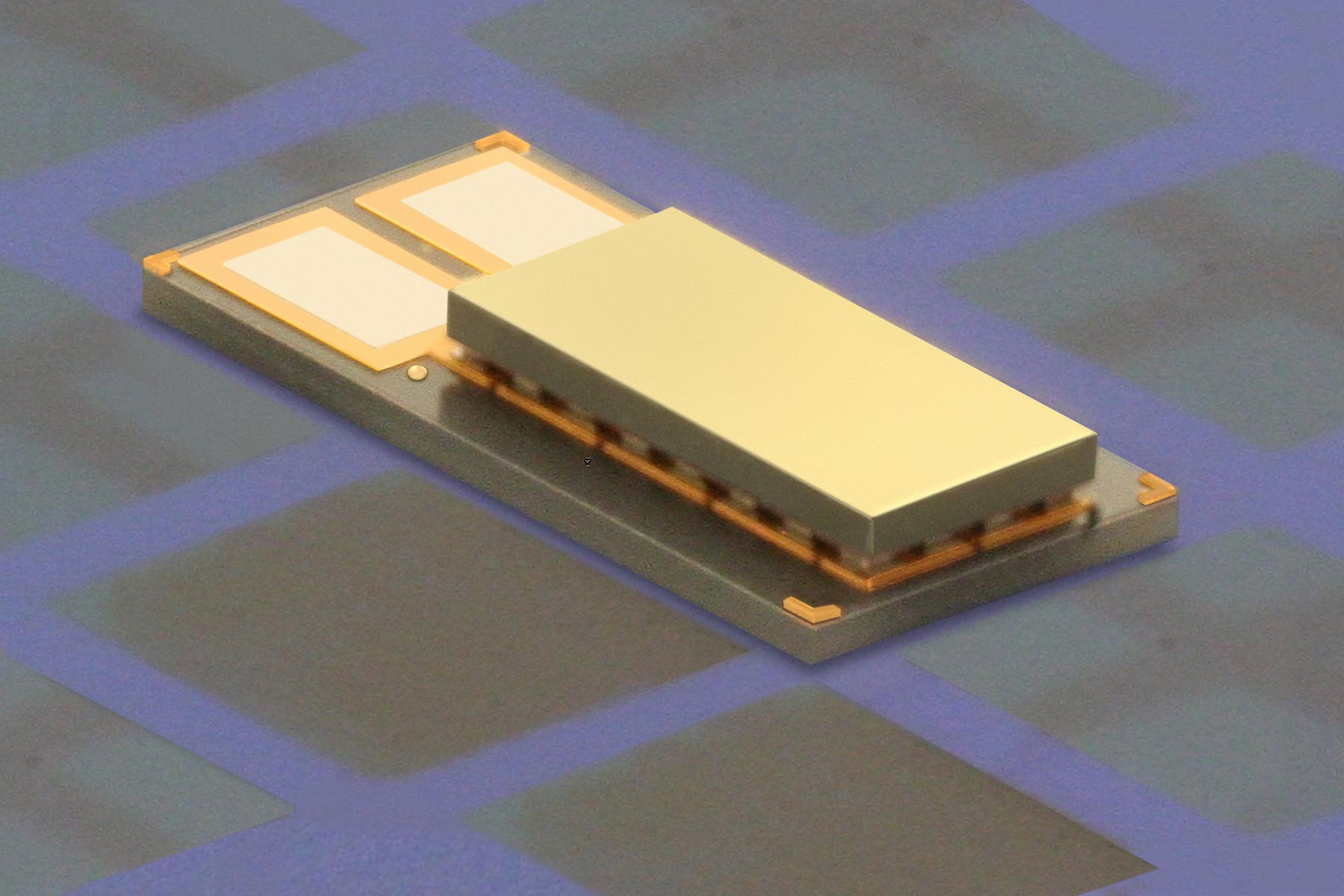

As the replacement for lead-based solder, Nextreme is using a Gold/Tin (AuSn) alloy. AuSn solder provides excellent joint strength and thermal conductivity. With a melting point of 278癈, AuSn enables the use of standard processes for the integration of Nextreme devices into photonic, microelectronic and optoelectronic device packages, such as laser diodes, semiconductor optical amplifiers and sensors, and to operate at higher temperatures.

"Gold/tin's higher melting point and its acceptance in the optoelectronics market make the use of this alloy advantageous during assembly of our micro-scale thermoelectric products," said Koester. "It's another breakthrough allowing us to offer thin-film thermoelectric devices that conform to standard assembly processes."

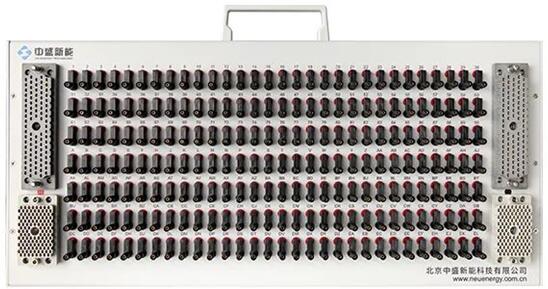

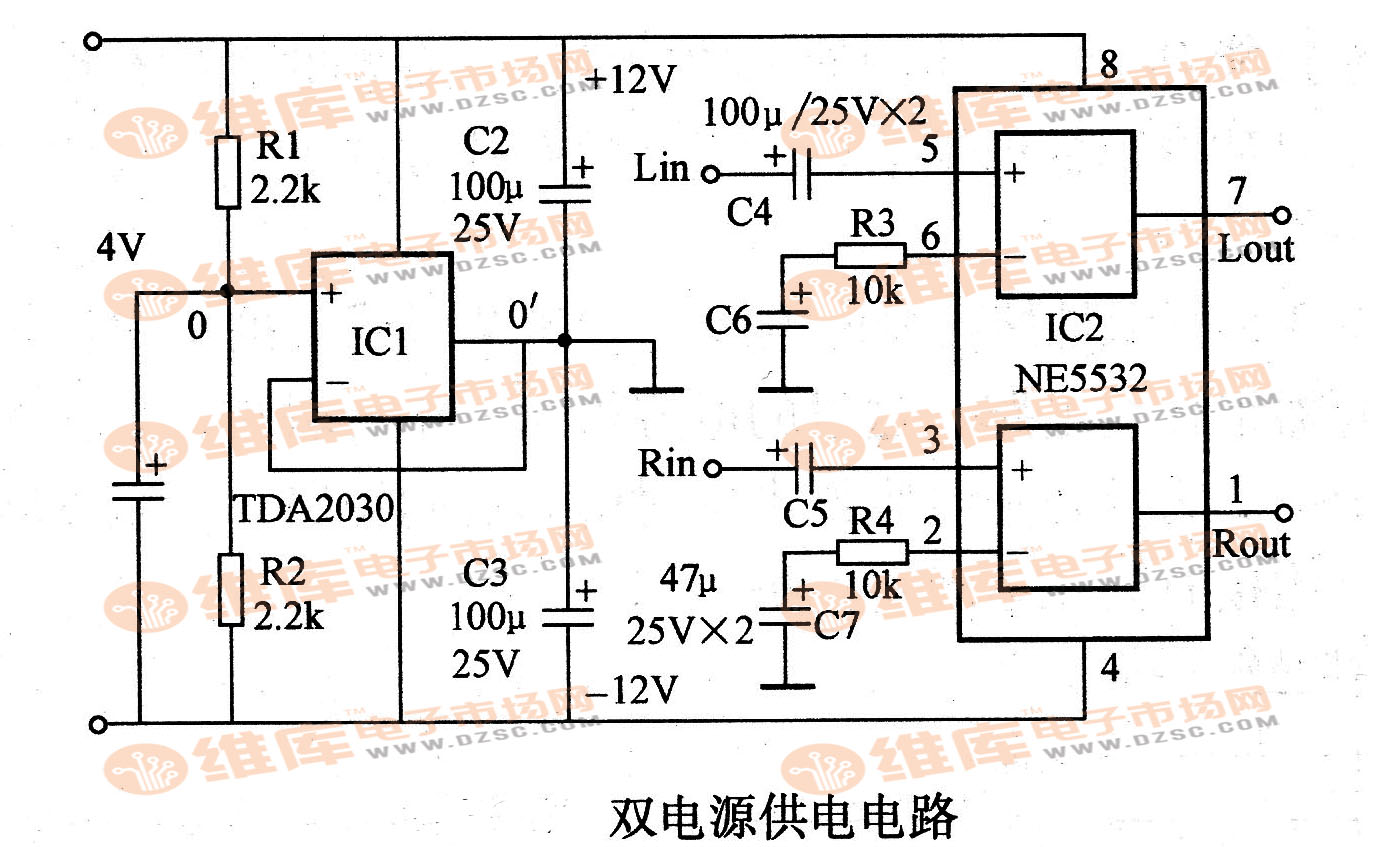

Nextreme's thin-film thermoelectric products are manufactured in volume with the Copper Pillar Bump process, an established electronic packaging approach that scales well into large arrays. The Thermal Copper Pillar Bump process integrates thin-film thermoelectric material into the solder bumped interconnects that provide mechanical and electrical connections for today's high performance/high density integrated circuits. The company began production manufacturing of its OptoCooler product line in July 2008.

相關閱讀:

- ...2017/01/06 17:05·Imagination與Socionext合作開發先進的視頻與顯示技術

- ...2017/01/06 14:16·Imagination與Socionext合作開發先進的視頻與顯示技術

- ...2016/11/24 22:03·CEVA 和NextG-Com合作提供面向低成本IoT應用市場的 集成式LTE Cat-M1 和 Cat-NB1 解決方案

- ...2016/04/27 10:23·全球領先的移動應用分發和變現平臺Appnext戰略進軍中國市場, 成功實現快速擴展與增長

- ...2016/04/26 10:01·Appnext與海信集團攜手提供完全定制的 移動應用體驗

- ...2015/12/10 11:20·LG Nexus™ 5X 智能手機選用 Qorvo RF Fusion™ 移動 Wi-Fi iFEM模塊

- ...· Efinix® 全力驅動AI邊緣計算,成功推出Trion™ T20 FPGA樣品, 同時將產品擴展到二十萬邏輯單元的T200 FPGA

- ...· 英飛凌亮相進博會,引領智慧新生活

- ...· 三電產品開發及測試研討會北汽新能源專場成功舉行

- ...· Manz亞智科技跨入半導體領域 為面板級扇出型封裝提供化學濕制程、涂布及激光應用等生產設備解決方案

- ...· 中電瑞華BITRODE動力電池測試系統順利交付北汽新能源

- ...· 中電瑞華FTF系列電池測試系統中標北京新能源汽車股份有限公司

- ...· 中電瑞華大功率高壓能源反饋式負載系統成功交付中電熊貓

- ...· 中電瑞華國際在電動汽車及關鍵部件測評研討會上演繹先進測評技術